This simplistic approach can lead to inaccuracies, especially in organizations with a wide range of products consuming resources at different rates. On the other hand, ABC costing focuses on tracing costs back to the root activities driving them and employs a more detailed, activity-focused approach. This enables companies to allocate overhead costs more accurately to the products consuming the resources. Leveraging the insights gained from ABC, businesses can craft competitive pricing strategies that take into account both their operational efficiencies and market dynamics. By employing a cost management strategy that encompasses an in-depth analysis of cost pools and cost drivers, organizations can pinpoint areas where they can streamline operations, reduce costs, and improve margins.

What Are the Five Levels of Activity in ABC Costing?

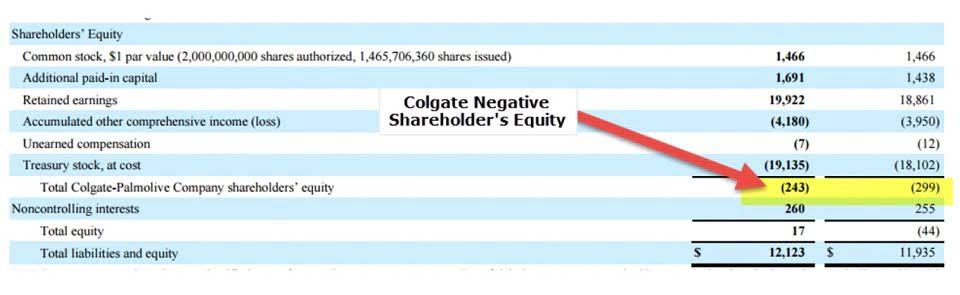

By understanding which items require more attention and resources, companies can make more informed decisions about purchasing, restocking, and resource allocation. This leads to more efficient operations and can significantly reduce waste and inefficiency in the supply chain. GAME has been employing traditional costing methods and applies factory overhead on the basis of labor costs. The products sell as fast as they can be produced so there is virtually no inventory. For a recent period CAPlayer sold 90,000 units and GLASSESong sold 110,000 units.

Sales & Distribution

Standing for Antecedent, Behavior, and Consequence, this model provides a structured approach to examine what happens before and after a behavior occurs. This article delves into the components, applications, and methodological foundations of the ABC model, exploring its effectiveness and limitations in behavior management and development. A cost driver is something that controls changes in the cost of an activity.

Efficient inventory management

Costs allocated to each activity represent the resources consumed by it. Create cost pools for those costs incurred to provide services to other parts of the company, rather than directly supporting a company’s products or services. The contents of secondary cost pools typically include computer services and administrative salaries, and similar costs. These costs are later allocated to other cost pools that more directly relate to products and services. There may be several of these secondary cost pools, depending upon the nature of the costs and how they will be allocated. It can help to avoid a large number of cost pools, to reduce the complexity of the ABC system.

Set key performance indicators for each class

As a result, it allows managers to allocate resources efficiently by focusing on the most valuable items first. Additionally, it can help managers predict future needs and ensure that the organization’s resources are deployed optimally. Keep more expensive products in class A, average adjusting entries expensive items in class B, and less costly items in class C. Managers can focus their attention on the most critical items in the inventory.

Get on the list to access free reading resources and tips!

On the other abc principle definition hand, this can also include frequent customers which make a lot of small purchases. These customers will definitely spend money on your storefront, but will never make much of an impact on your sales and profit. As a purchasing manager, understanding your sales over a certain period will help you evaluate and segregate which product belongs in which category i.e., A, B, or C. This will also assist the purchase manager in analyzing what to buy, and in what quantity.

- With every transaction and process modification, the system learns and adjusts, providing continually improved costing precision.

- This resulted in a more equitable cost distribution and informed decisions about where to focus resource optimization efforts for better cost control.

- Traditional costing is simpler but less specific than activity-based costing.

- Use an SKU’s consumption volume only when conducting ABC analysis for physically organizing your inventory.

- This enables companies to allocate overhead costs more accurately to the products consuming the resources.

- Inventory ABC analysis can help your factory executives make the right data-driven decisions while improving your ability to respond quickly to market requirements.

- The ABC Principle, also known as the Pareto Principle or the 80/20 rule, can greatly benefit organizations in achieving optimal procurement results.

- ABC analysis is derived from the term “The Pareto Principle” named after an Italian economist Vilfredo Pareto, also called 80/20 rule.

- If we’re looking on atimeline drafted for one month, purchasing “A” items can be done weekly, “B”items in a bi-weekly frequency and “C” items every 4 weeks.

- It will discuss the Pareto principle, ABC classification, how to use it in inventory management, and its advantages, disadvantages, best practices, and history.

- Despite its advantages, ABC does come with its own set of challenges and limitations that can influence its overall effectiveness.

I assumed that project sponsorship would transfer from a departing managing director to the incoming one QuickBooks ProAdvisor without issues. I went ahead and updated the project documentation to reflect the new sponsor. However, I failed to communicate this change to the incoming managing director. Later, the new sponsor humorously remarked, “Oh, thanks for making me the new sponsor. It would have been nice if you had informed me.” This taught me that assumptions around roles and expectations should always be clearly communicated. The ABC principle is often linked to learning fundamentals, as famously sung by the Jackson 5 in ABC.